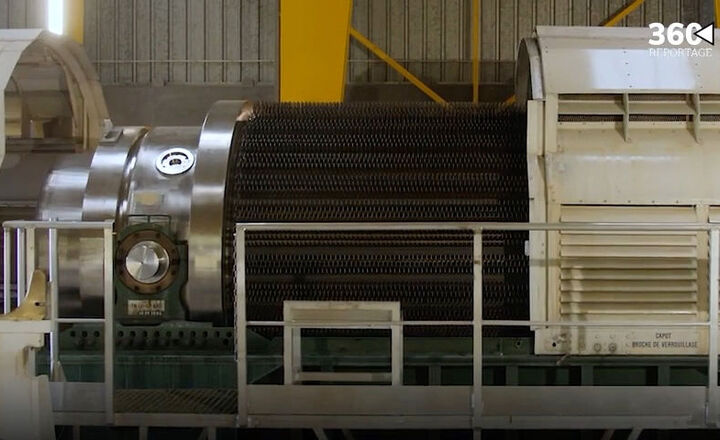

Heavy equipment for the nuclear industry

ATB Group is an international leader manufacturing and supplying of heavy equipment for nuclear industry all over the world.

Since the early 70’s, ATB has been among the most important international players in the design and construction of sophisticated nuclear components. Due to the recognized capabilities for welding and machining pressure vessels, ATB has been qualified by some of the most important Nuclear Engineering Companies (Westinghouse, Framatome, GE) for the manufacturing of critical components of the Nuclear Island.

Such components, from the Reactor Vessel to the Pressurizer, are part of Nuclear Plants or Nuclear Research Centers in Europe and in the USA.

During the last few years, ATB has focused its commercial and industrial efforts on a market sector that has grown steadily: containers for the transportation and storage of High Level Radioactive Materials (HLRM).